The Next Generation of Cultivation Floor Coatings

At Cannafloors, we specialize in providing innovative flooring solutions designed specifically for cannabis cultivation facilities. Our high-performance, FDA & USDA approved urethane cement and polyaspartic coatings are engineered with nano hole technology to withstand the unique challenges of the cannabis industry, including high humidity, UV exposure, and chemical use. Our flooring systems are not only durable but also ensure a clean, safe, and long-lasting environment for your grow rooms, manufacturing/processing areas, and fertigation spaces. With Cannafloors, you can trust that your facility will have the reliable, resilient flooring it needs to thrive in even the toughest conditions. Experience the difference in quality and performance.

WHAT IS CANNAFLOORS?

Cannafloors is a Polymer Urethane Cement "thin mil" coating system with a polyaspartic top coat designed specifically for the cannabis industry to do what epoxy can't. Cannafloors is formulated with nano hole technology making it a breathable system that thrives in the wet humid environments where epoxy tends to chip peel lift and fail.

Slip Resistant

Textured floors with a variety of options for non-slip additives to meet/exceed worker safety needs.

Thermal / Chemical Resistant

Can withstand extreme temperature shifts and harsh chemical cleanings and sanitation wash downs.

Breathable System

Nano Hole Technology allowing the floors to breath and not trap the moisture which is the leading cause of floor failures.

WHY SHOULD I USE CANNAFLOORS VS. EPOXY?

The environments created inside grow facilities are unlike the environments created in most other industries. Having a floor coating system that will not chip, peel and lift because of moisture issues gives you the peace of mind knowing your facility will always be compliant and that micro organisms, bacteria or pathogens will not be able to grow and affect your yields. Cannafloors Coating system is a stronger more durable coating when compared to epoxy. Cannafloors has shock absorption qualities and is able to expand and contract with the movements of the concrete as temperatures in the rooms change. Epoxy's chemical structure does not allow it to expand and contract with the movements of the concrete. Epoxy also does not have shock absorption qualities and its natural characteristic is to chip and shatter with impact.

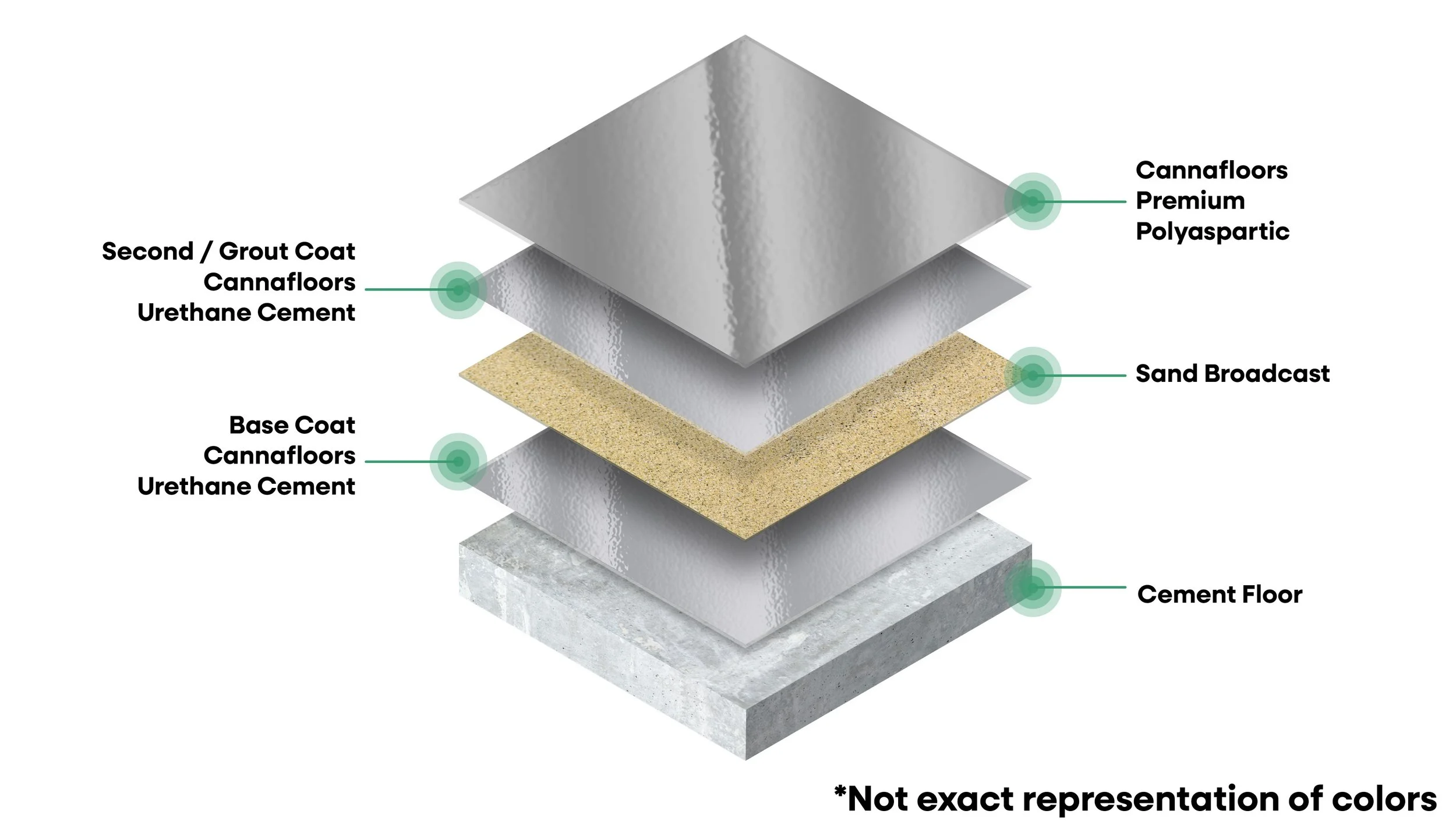

Cannafloors Coating System

Cannafloors Urethane Cement:

is a 3-component Thin mil polyurethane concrete floor coating system. It is specially formulated for the environments created in Cannabis facilities. Cannafloors Urethane Cement is a seamless antimicrobial flooring that is FDA & USDA approved for application in cannabis facilities. It can withstand the harsh humid climates and the constant changes in temperature. Cannafloors Urethane Cement is a breathable, 100% solids material that allows for vapor release. With Cannafloors, the moisture drawn to the surface of the slab can expel and not cause damage to the bond resulting in flooring failures. Cannafloors Urethane Cement is 100% BPA free.

Cannafloors Premium Polyaspartic:

is our top coat material. This is a 2 component, pigmented polyaspartic. It is formulated to withstand continuous cleanings, harsh chemicals, extreme UV exposure, heavy foot traffic and is sustainable in a wet environment. Cannafloors Premium Polyaspartic is a seamless antimicrobial coating that is FDA and USDA approved for application in cannabis facilities. It leaves a high gloss finish for high reflectivity and easy cleanability. Cannafloors Premium Polyaspartic is a 100% BPA free product.

Sand Broadcast:

is a layer of fine grit sand that is thrown/broadcast on top of the Base Coat/First Layer during the application process. The sand broadcast increases the shock absorption of the floors impact resistance. It is also to assist in creating the nano holes needed for the system to maintain its breathability of the floor.